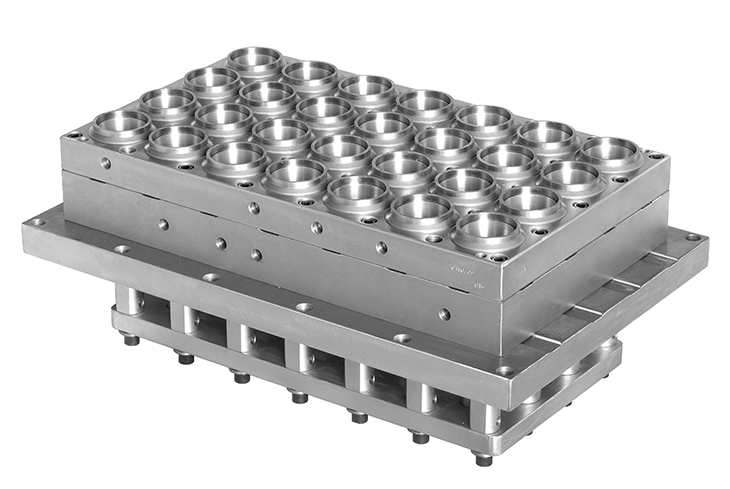

Features:

This Big Capacity Automatic Hydraulic Computerized Plastic Cup Making Machine is specially designed by our experienced technical team according to customers’ high production capacity requirements. The energy consumption is about 15-20% higher, but production output is about 40% higher per hour.

1.Four-pillar structure, durable # 45 chrome plated steel with good rigidity and abrasion resistance.

2.The ascending and descending of mold plate is controlled by hydraulic, which ensures less noise and vibration.

3.Sixteen heating zones, controlled by intelligent temperature controller with tolerance within 1.0℃

4.Far infrared radiation ceramic heater ensures high safety and reliability.

5.Double-row feeding chain with gear and pin, water cooling pipe designed into chain guide ensures high cooling efficiency and water saving, inside part covers by stainless steel , chain guide adopts nitriding #45 steel , which ensures its hardness and durability .

6.Low barycenter and height of blowing out finished products as well as steady running ensures easy operation and friendly viewing.

7. Frequency-conversion-driven sheet feeder, high precision sheet feeding with tolerance ranging from0.5mmto5mmensures less waste.

8. All motors are equipped overwork-protected.

9. Imported SIEMENS PLC human-machine interface control ensures smooth and exact operation

10. Waste sheet rewinder installed at the end of the machine with max sheet roll diameter of0.8mand saves space.

11. Automatic Sheet Roll Loading and Unwinding Device makes job easy.

Main Technical Parameters:

|

Model |

HYC-720 |

HYC-850 |

|

Material |

PP,PE,PS,PVC,PET,ABS,HIPS,PLA,(biodegradable sheet) |

|

|

Sheet thickness |

0.3-2.0mm |

|

|

Suitable Sheet width |

720mm |

850mm |

|

Max forming area |

720×450mm |

850×565mm |

|

Max forming depth |

120/180mm |

120/180mm |

|

Running Speed |

15-30 strokes/min |

15-30 strokes/min |

|

Aprrox. Energy consumption |

40-50kw/hr |

50-60kw/hr |

|

Main motor power |

15Kw/ 6P |

15Kw/ 6P |

|

Power supply |

380V / 50Hz(3-P, 4-wires) |

380V / 50Hz(3-P, 4-wires) |

|

Voltage |

0.6-0.8Mpa |

0.6-0.8Mpa |

|

Air volume required |

2500~3500L/min |

2500~3500L/min |

|

Water volume required |

40~45L/min |

≦50 L/min |

|

Machine weight |

About 5.0T |

About 5.5T |

If you have any enquiry about quotation or cooperation, please feel free to email us at market@jhsmachinery.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

| Subject: | ||

|---|---|---|

| *Message: | ||

| *Name: | ||

| *Email: |

(Please make sure your E-mail address is correct otherwise the recipient will not be able to reply.) |

|

| CompanyName: | ||

| Tel: |

(Please make sure your Business Phone is correct otherwise the recipient will not be able to reply.) |

|

| Fax: | ||

| Address: | ||

| Products: | ||

|

|

- Sheet Extrusion Line

- Plastic Cup Making Machines

- Cup Printing Machine

- Plastic Vacuum Press Forming Machine

- PS Foam Fast Food Box Production Line

- Cup/Glass Filling&Sealing Machine

- Auxiliary Equipments

- Welcome to visit our Stand D82 in VietnamPlas Fair from Oct.,3th-6th, 20192019.09.25

- Congratulation: our new factory starts construction!!!2018.08.19

Contact & Location

Contact & Location

Cell: 0086-137 1993 2305(whatsapp/viber/wechat)

Fax: +86-754-82480335

MSN:

SKYPE: jhsmachinery

E-mail: market@jhsmachinery.com

Contact Person: Jack from JHS Machinery

You are here:

You are here: